Advancing robotic research and application in industry

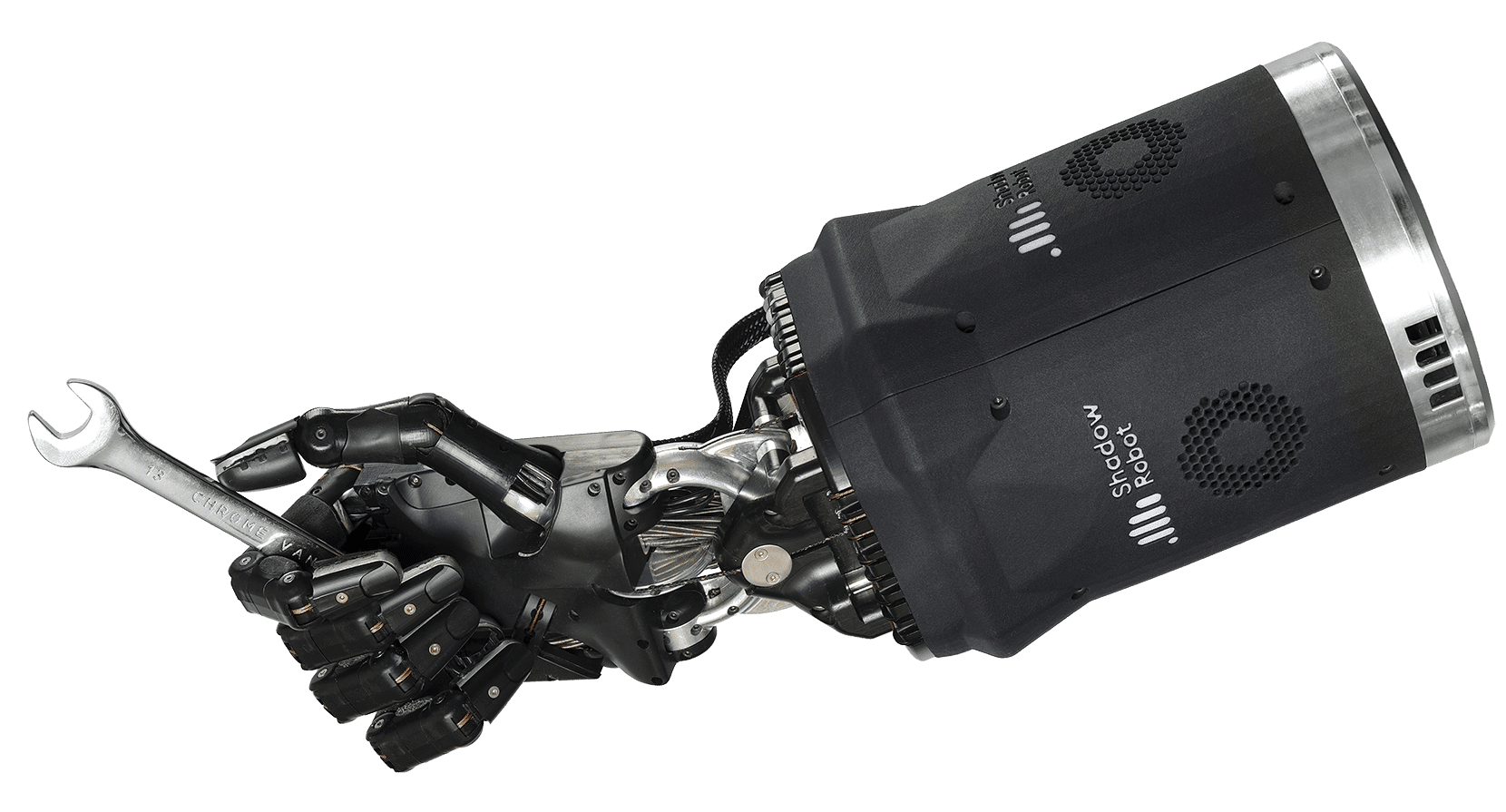

The Shadow Dexterous Hand is the most advanced 5-fingered robotic hand in the world.

Offering unprecedented accuracy, The Hand can manipulate tools and objects with greater precision than ever before. Our technology opens up new avenues for research in robotics and artificial intelligence, and enables the refinement of existing technologies.

With 2 extra DOF at the wrist, it provides flexibility, optimises accurate positioning of the hand, and helps avoid singularities when mounted on a robot arm.

Abduct/Adduct

Each finger has an independent side-to-side motion for impressive in-hand manipulation and other movements with advanced dexterity

Provides postural stability, shock mitigation, and bending to facilitate dexterous motion.

A range of different finger tactile tips are available depending on your dexterity needs

uses and benefits

Over 20 years' research and development make The Dexterous Hand a trusted component for research and industry.

Pressure Sensor Tactiles (PSTs) fitted as standard in the fingertips.

Fully ROS integrated, for use as a research and development tool and as testing hardware for AI and Machine Learning.

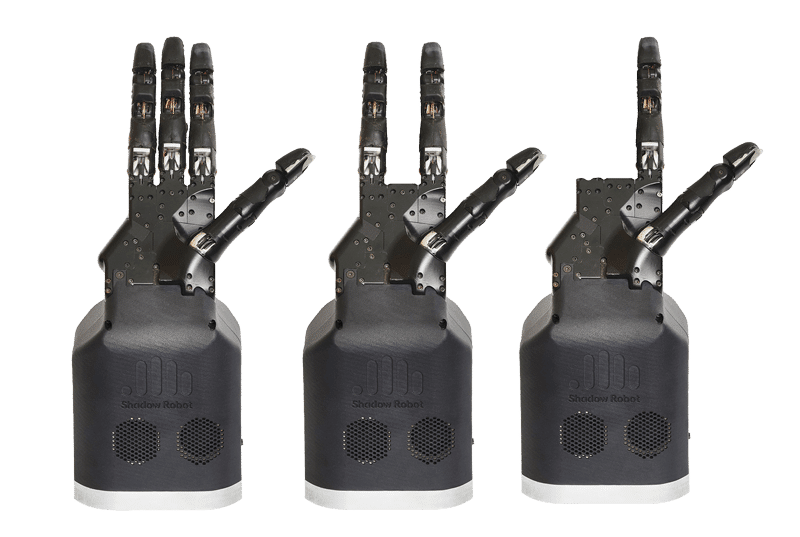

Discover Dexterous lite

The Lite series gives you more flexibility to meet your project needs. Choose from the Lite, Extra Lite and Super Lite versions of our robot hands.

Compact and lightweight - removing a finger from each successive model decreases their weight, making the Lite series particularly well suited for mobile manipulation projects or reducing the load on robot arms

Energy-efficient - Dropping from the five fingered hand to the four fingered Lite delivers 35% power saving, helpful for battery powered systems.

Affordable - each model offers savings, making it possible to achieve precision manipulation on a budget

| Overview | Shadow Dexterous Hand | Shadow Dexterous Hand Lite | Shadow Dexterous Hand Extra Lite | Shadow Dexterous Hand Super Lite |

|---|---|---|---|---|

| Degrees of Freedom (DOF) | 20 actuated DOF and a further 4 under-actuated movements for a total of 24 joints | 13 DOF across 16 joints | 10 DOF across 12 joints | 7 DOF across 8 joints |

| Overall Weight | 4.3 Kg | 2.4 Kg | 2.1 Kg | 1.8 Kg |

| No. of Fingers | 4 + 1 (thumb) | 3 + 1 (thumb) | 2 + 1 (thumb) | 1 + 1 (thumb) |

| No. of Actuators | 20 DC motors | 13 DC motors | 10 DC motors | 7 DC motors |

| No. of Finger Joints | 4 | 4 | 4 | 4 |

| No. of Thumb Joints | 5 | 4 | 4 | 4 |

| No. of Wrist Joints | 2 | 0 | 0 | 0 |

| No. of Tip Pressure Sensors | 5 | 4 | 3 | 2 |

| No. Inertial Measurement Units (IMU) | 1 | 1 | 1 | 1 |

| No. of Tendon Load Sensors | 40 | 26 | 20 | 14 |

| Control loop rate through host | 1kHz (EtherCat protocol) | 1kHz (EtherCat protocol) | 1kHz (EtherCat protocol) | 1kHz (EtherCat protocol) |

| ROS Open Source Platform |  |

|

|

|

| Easily Integrated on Robot Arms |  |

|

|

|

| Upgradable With Other Components |  |

|

|

|

Dexterous Hand Options

System options

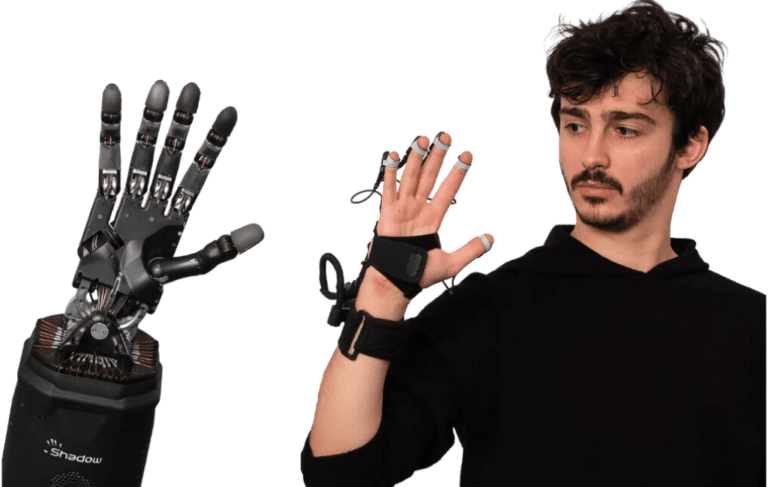

Shadow Glove

Intuitive control in the palm of your Hand.

The Shadow Glove is fully optimised to work with our Dexterous Hands, accurately mimicking your movements to provide unparalleled precision with minimal training.

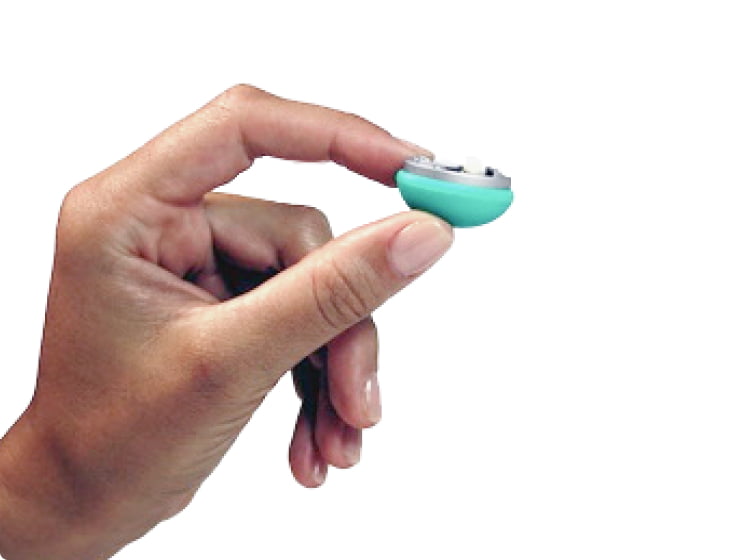

Produced by SynTouch, the BioTac is a revolutionary tactile sensor capable of detecting the full range of sensory information that human fingers can identify, including forces, micro-vibrations, and temperature.

Add an Arm

Our Hands are more mobile when attached to an arm for extendable reach. We can provide each Hand with a safe and flexible 6 Degrees of Freedom (DOF) industrial robotic arm from Universal Robots.

Do you have a project that would benefit from The Dexterous Hand?

Contact us to talk through your requirements, discuss pricing and book a demo.

Are you a researcher?

Discover how our robot hands are being used for research by academic institutes!