Our consultants are on hand to analyze, design and prototype advanced robotics technologies tailored to your unique challenges.

We won’t confuse you with jargon or overcomplicate your project. We’ll look at how our existing technology can help, and if we discover that it’s better to use something else we’ll work with you to achieve it.

What our team offers you

Our engineering team have been applying robotics solutions to technical challenges for over two decades.

Through a consultative approach we define, analyze, and propose tailored engineering solutions.

Thanks to our inhouse lab, we take proof of concepts to the prototyping phase in partnership with your team.

We provide the full codebase, design and build prototypes, and document all required aspects of the solution.

Whether for internal or external purposes, we collaborate on creating promotional communication assets throughout the project.

Our projects

Moley – The World’s First Robotic Kitchen Chef

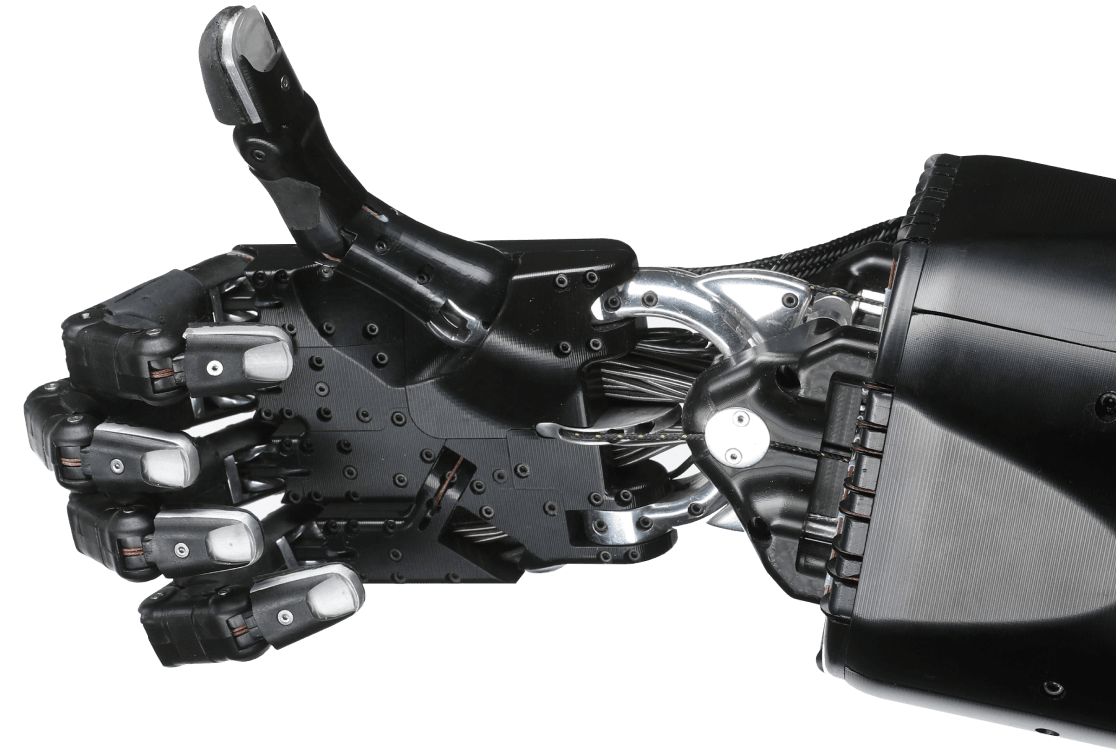

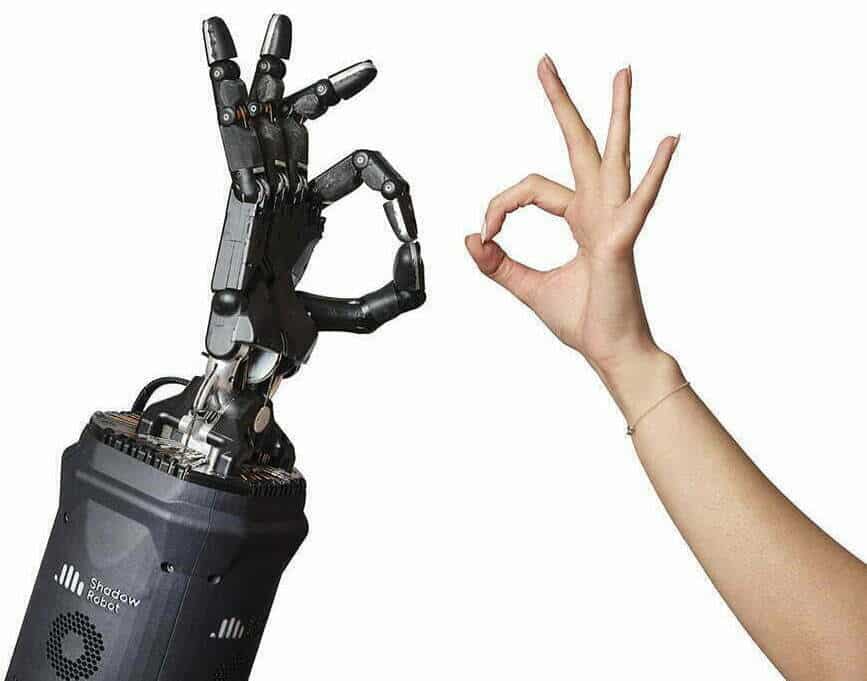

The highly advanced, fully functional robot, using our Shadow Dexterous Hands, is integrated into a beautifully designed, professional kitchen, and cooks with the skill and flair of a master chef. The robot can do everything from assembling and chopping all the ingredients, cooking on the hob, or putting food in the oven, and finishing up by cleaning the dirty pans.

Our projects

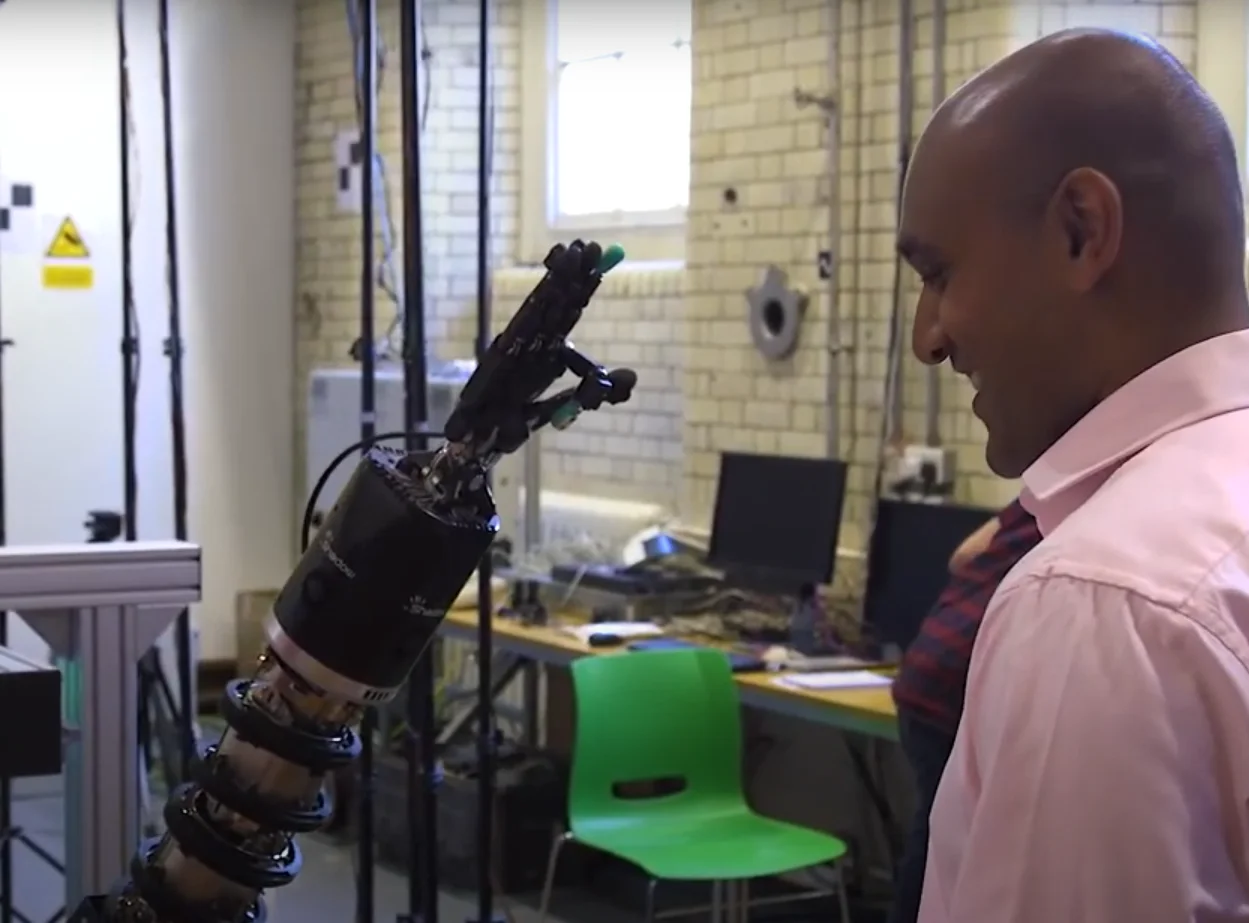

Prof Tickle – The Amorphous Dexterous Snake Arm Robot

This project provides consultancy to the prestigious University College London (UCL) and OC Robotics to create ‘Prof Tickle’ – a heroic snake-arm robot with our Dexterous Hand on the end. Capable of moving into difficult and inaccessible places, the results demonstrate the robot’s ability to perform dexterous tasks across large distances. Why the name? Well, it pays homage to the project’s inspiration Mr Tickle from the Mr Men children’s books. Like the character, the unique robot extends its arms to reach and perform everyday tasks. It’s featured on BBC Earth Lab (03:52-6:18).

Our projects

How to Build a Bionic Man – Built Exclusively for Channel 4

Conceived as a literal response to the question: how close is bionic technology in catching up with – and even exceeding – the capabilities of the human body? Shadow takes on the role as a technical consultant for the project, responsible for designing the bionic man and the integration of parts from high-end manufacturers. The consultancy project captures immense media attention, later unveiling as an exhibit at London’s Science Museum.

Testimonials

Moley – The World’s First Robotic Kitchen Chef

It’s the ultimate sous-chef.

Tim Anderson, 2011 BBC MasterChef Champion

Explore solutions to all your dexterity challenges, ideas or projects.